Written by J.C. Arènes

VP Sales & Service

Jan 12, 2022

In our relentless pursuit of industrial advancement and the efficient utilization of our planet's resources, we often overlook the silent toll such processes can take on the environment. Among these resources, water stands out as a fundamental pillar supporting life in all its forms. In this context, the technology of hydrocarbon leak detection in process cooling water emerges not just as an innovation but as an essential safeguard. Through the meticulous application of science and engineering, we find ways to mitigate the environmental impact of industrial operations.

This blog explores the critical role of heat exchangers in hydrocarbon processes, the environmental challenges posed by hydrocarbon leaks, and the sophisticated technologies developed to detect and manage such leaks. Join us as we explore the sophisticated interplay of engineering and environmental science behind hydrocarbon leak detection.

What you’ll learn:

- Heat Exchangers and Environmental Care: Discover the role of heat exchangers in industrial processes, the importance of detecting leaks early, and the impact on the environment.

- Detection Science and Technology: Learn about the science behind detecting hydrocarbons in water and the latest technologies, like Novatech’s sparger system, for quick and accurate detection.

- Choosing Detection Methods: Understand how different technologies are chosen for detecting leaks, focusing on sensitivity and accuracy to protect the environment.

- Real-World Impact: See how tailored detection systems are used in industries to meet safety standards, protect water quality, and support sustainability.

The Industrial Necessity of Heat Exchangers.

Hydrocarbon processes often require heat to achieve the desired reactions. Heat exchangers are sometimes used to recover the heat of the process fluid post-reaction or simply to cool the fluid before transportation or storage.

Water is commonly used as a cooling fluid in closed circuits to serve the entire plant site or in once-through arrangements from a nearby water source such as a river or lake. These leaks may be tiny (pinhole) in size, or catastrophic in nature. Detecting the tiny leaks allows the plant operators to take corrective action and address the issue, long before it becomes disastrous in nature.

Depending on the type of process stream being cooled, the hydrocarbon leaking into the water may be:

- Gaseous

- A two-phase liquid

- Dissolved

The Environmental Challenge: Detecting Hydrocarbon Leaks.

While Novatech has developed solutions for detecting all these scenarios, the hydrocarbon sparger targets hydrocarbons in solution, which are challenging to detect with traditional optical techniques.

The Science Behind Hydrocarbon Detection: Understanding Henry’s Law.

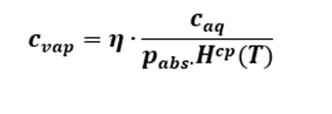

Henry’s Law governs the behavior of hydrocarbons in solution. It relates the concentration of a vapor ![]() in contact with water to the concentration in solution

in contact with water to the concentration in solution ![]() . While Henry’s constant varies with the species and is a strong function of temperature, at equilibrium, the concentration in the gas phase can be estimated from:

. While Henry’s constant varies with the species and is a strong function of temperature, at equilibrium, the concentration in the gas phase can be estimated from:

As the pressure in Henry’s Law is in the denominator, we can increase the concentration in the vapor ![]() by decreasing the pressure in our system. Novatech’s hydrocarbon sparger technology operates under vacuum, thereby dramatically increasing its ability to sparge dissolved hydrocarbons into the vapour space.

by decreasing the pressure in our system. Novatech’s hydrocarbon sparger technology operates under vacuum, thereby dramatically increasing its ability to sparge dissolved hydrocarbons into the vapour space.

Innovating Detection: Novatech’s Hydrocarbon Sparger System.

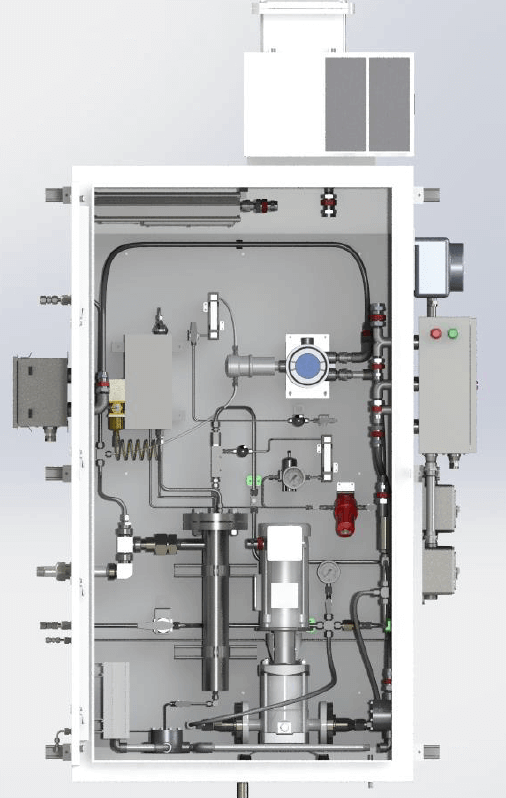

The system consists of a water-driven eductor or jet pump, which creates an environment where the water and a sparge gas (typically instrument air) can mix under vacuum. The eductor’s driving force is the very cooling water we are monitoring. From there, the well-mixed two-phase fluid is directed to a hydraulic separator, allowing the hydrocarbon-enriched gas phase to be separated from the cooling water. The separator’s design provides a hydraulic head, sufficient to drive the gas through the conditioning portion of the system, while the cooling water is allowed to drain by gravity from the unit.

From Theory to Application: How the Sparger Works.

The gas from the separator will be saturated with moisture at this point, governed by the temperature of the water it was in contact with. Before allowing the gas to enter the detection unit, a sample conditioning system will address any dew point concerns.

Choosing the Right Detection Technology.

The desired detection limit will drive the choice of detection technology and determine whether a specific analysis is required. Traditional infra-red gas detectors can be used since the concentration of hydrocarbons in the vapour phase will be several hundred (if not >1000) times greater than that in the liquid phase. Thus, a traditional gas detector with a measurement range of 0 – 100% LEL (or 0 – 50,000ppmv CH4) may have an equivalent measurement range of 0 – 5,000ppm in the liquid (if we assume 1000:1 equivalency). This has been demonstrated through empirical testing by Novatech and can also be validated by the client using the system’s septum seal, which allows the injection of known liquid hydrocarbon volumes into the liquid phase.

The Power of Precision: Enhancing Sensitivity in Leak Detection.

Greater sensitivity can be achieved with non-dispersive Infra-red gas analyzers capable of seeing leaks in the ppb range. Furthermore, a gas chromatograph can extend the detection limits even lower and provide the added benefit of speciated analysis. Speciated analysis could enable a plant operator to pinpoint the source of a leak when monitoring a cooling water stream servicing several heat exchangers.

A Commitment to the Environment: The Advantages of Rapid Detection.

Novatech‘s hydrocarbon sparging technology is a reliable and robust means of detecting hydrocarbon leaks in plant cooling water. It addresses the need for a rapid detection method that runs continuously with minimal need for maintenance or intervention. Unlike traditional capture analysis techniques which may require tens of minutes to perform an analysis, the response time of the Novatech sparger is measured in seconds. Custom-made to the specific requirements of the application, the installation location & environment, and electrical safety codes, Novatech’s hydrocarbon sparger systems can form an integral part of a plant’s environmental protection strategy.

Excerpts from: Osprey, J., A Robust Sparging Technique for Continuous Monitoring of Hydrocarbons in Process Cooling Water. Proceedings – ISA Analysis Division Symposium, 2016.

Looking to dive deeper into hydrocarbon leak detection solutions? Our webinar is your essential resource. Discover the latest advancements and insights, straight from experts in the field.

Be the first to read our articles

Written by J.C. Arènes

VP Sales & Service

Write to me at arenesjc@novatech.ca