Gas detection has come a long way from the days of canaries in coal mines. The technology has advanced, but the places we need to monitor? They’re as tough as ever.

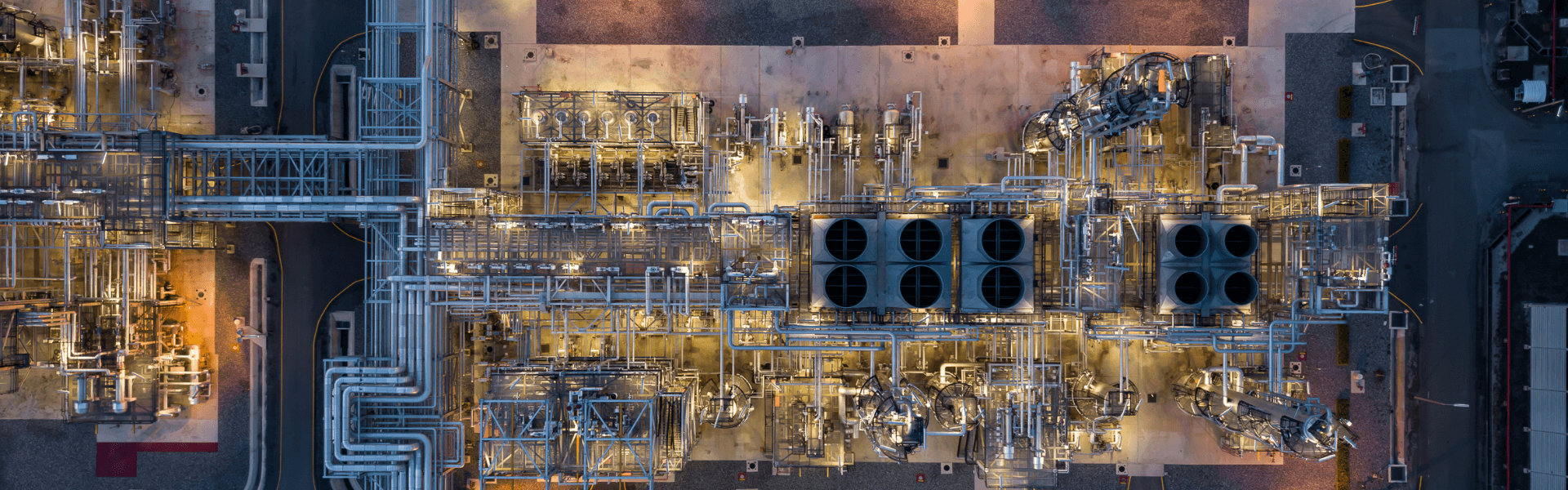

Today’s industrial facilities are complex, layered, and often unforgiving. The real challenge isn’t just what we’re trying to detect—it’s where. From floor sumps and overhead beams to obstructed corners and high-risk zones, the most critical spaces are often the hardest to reach.

This article explores those real-world challenges and offers practical, proven strategies to make safety possible, no matter how complicated the layout gets.

What you’ll learn:

- The key challenges of installing detectors in real-world industrial settings

- How gas behaviour impacts sensor placement—and why it matters

- When remote-mounted sensors are the right choice

- How aspirated detection systems provide access without compromise

- Best practices for designing detection strategies that ensure long-term safety and compliance

Rethinking Detector Placement — Beyond the Blueprint.

It’s easy to imagine perfect detector placement in a CAD drawing. But walk into a real facility, and the theory meets reality—fast.

Picture this: towering ceilings, tight crawl spaces, heavy-duty equipment everywhere, and access platforms that end several metres short of the problem area. Add in hazardous zones that require explosion-proof equipment, and the installation becomes a logistical maze.

The solution? Tailoring placement to the gas in question and the conditions on the ground. That might mean mounting detectors:

- Near ceilings for lighter gases like hydrogen or methane

- At floor level or in sumps for heavier gases like propane or H₂S

- Inside ducts or air returns where airflow is limited or unpredictable

- In zones with strict safety classifications that limit what hardware you can use

Every decision has a ripple effect: on calibration, maintenance, accessibility, and—ultimately—on safety.

Gas Behaviour Isn’t Theory—It’s Survival.

In harsh industrial environments, understanding how gases behave can mean the difference between prevention and disaster.

Gases don’t stay neatly in one place. They rise, fall, disperse, and accumulate based on their unique physical properties and the dynamics of the environment around them.

Here’s what drives that movement:

- Molecular weight – Light gases rise; heavy ones settle

- Temperature & pressure – Affect speed, dispersion, and reach

- Ventilation & airflows – Dilute, trap, or redirect gas clouds

Take hydrogen sulphide, for example: heavier than air, invisible, and deadly. In a poorly ventilated sump, it can silently reach toxic concentrations without warning. No alarm will ever go off unless your detector is placed precisely where the gas collects.

Sensor placement isn’t just about convenience—it’s about aligning with the laws of physics.

When Access Isn’t Possible: The Role of Remote-Mounted Detectors.

In many situations, placing a sensor where it needs to be puts technicians where they shouldn’t be.

That’s where remote-mounted detection systems come into play. These configurations let you install the sensing head exactly where the gas risk is highest, while keeping the display and electronics somewhere safe and accessible.

But it’s not just plug and play. Designing an effective remote system means accounting for:

- The ability to initiate remote calibrations with accuracy

- Reliable gas delivery through long or angled tubing

- Proper flow rates to maintain response times and measurement integrity

- Suitable materials to avoid leaks, pressure drops, or corrosion over time

It’s not just about getting a signal—it’s about trusting that signal when it matters most.

Tough Spot? Meet the iTrans 2 Fixed Gas Detector.

Dual sensors. Remote mounting. Built for the hardest-to-reach, highest-risk zones—where smart detection counts most.

Aspirated Detection: When Even Remote Isn’t Enough.

Sometimes, even a remote sensor head isn’t viable. Maybe the environment is too corrosive. Maybe it’s a classified space. Maybe the maintenance risk is just too high.

In these cases, aspirated systems provide a unique solution.

These setups use pumps to pull ambient air from the target area and route it back to a centralized detector located in a safe, controlled environment. It’s like giving your detection system a long-distance airway—one that can breathe in data without exposing personnel or electronics to risk.

Aspirated systems are particularly effective in:

- Cleanrooms, where sensors could introduce contaminants

- Humid or washdown areas, where splashes or steam can damage exposed heads

- Toxic zones, where isolating electronics extends equipment lifespan

- Static zones, where airflow is so limited that gas diffusion takes too long

With accessories like flow cells, dust filters, and deluge guards, these systems can be customized for virtually any condition, without sacrificing reliability or maintenance access.

Strategy First: Design with Detection in Mind.

Here’s the truth: many gas detection headaches are born during the design phase.

Waiting until the final stages of a project to plan sensor locations almost always leads to compromises. Smart facilities design their detection strategy early—ideally before construction even begins.

What that looks like:

- Running a gas hazard assessment during early engineering

- Consulting vendors on sensor capabilities and certification needs

- Building access routes for calibration and service

- Pre-planning remote or aspirated systems where required

Gas detection isn’t a bolt-on—it’s a core safety system. Building with that mindset pays off for years to come.

Tough install? Meet a tougher detector…

The Meridian Gas Detector is SIL 2-certified, supports remote calibration, and handles both toxic and combustible gases — all in one rugged, flexible device.

When Detection Gets Tough, Strategy Becomes Non-Negotiable.

In industrial environments, installing a gas sensor is never just about hardware—it’s about risk management.

You’re not just checking a compliance box. You’re protecting lives.

And the more complex the facility, the more critical it is to have a detection strategy that adapts to your environment, understands gas behaviour, and embraces the right technologies—remote heads, aspirated systems, or both.

At Novatech, we don’t just install detectors. We help facilities engineer smarter safety systems from the ground up—because complexity should never be an excuse for compromise.

Be the first to read our articles

Written by Félix Lalande-Hendershot

Technical Sales Representative

Write to Félix at: lalandehf@novatech.ca