Written by Samuel Evans

Global MAX Business Development Leader at Thermo Fisher Scientific

January 15, 2026

What you’ll learn in this article:

By the end of this piece, you’ll understand:

- Why can transported CO₂ form corrosive acids even with low-level impurities

- Which contaminants pose the greatest risk to pipelines and storage wells

- Why continuous, online purity monitoring is essential for CCUS safety

- How FTIR spectroscopy detects ppb–ppm impurities in real time

- What makes the Thermo Scientific™ MAX-Bev™ System suited for CO₂ purity assurance

- How automated validation and multi-stream scalability simplify operations

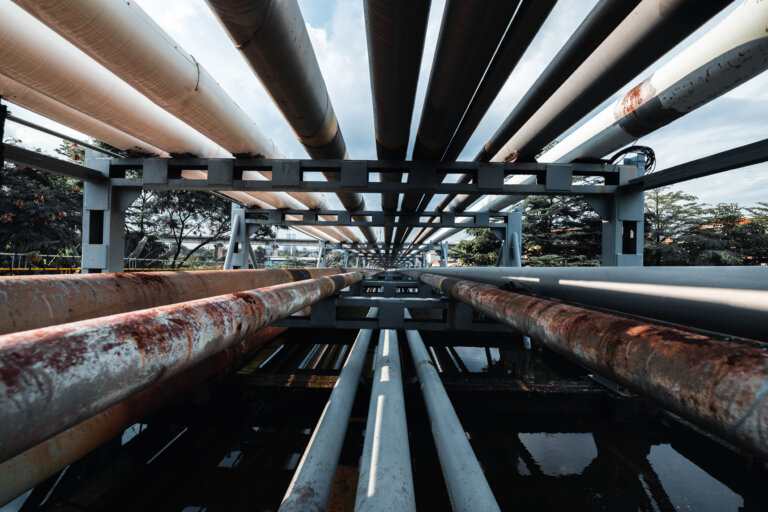

The Chemistry Behind CO₂ Transport Risk.

Pipeline-grade CO₂ is rarely perfectly pure. Small amounts of water, nitrogen oxides, sulphur oxides, hydrogen sulphide, and oxygen are often present, depending on the capture process and upstream cleanup.

Research shows that when CO₂ containing these trace impurities is compressed and transported, reactions occur that can generate:

- Sulfuric acid (H₂SO₄)

- Nitric acid (HNO₃)

- Elemental sulphur and other reactive sulphur species

Even when impurities remain at levels considered acceptable, the acids formed can significantly accelerate metal corrosion. Under the right conditions, they can attack pipeline steel, compromise welds, and shorten the lifespan of valves, seals, and instrumentation.

The chemical risk is real — and it increases as CCUS infrastructure scales.

"Once CO₂ enters a pipeline, conditions can change quietly, continuously, and without warning."

Why Continuous Monitoring Is Essential.

Traditional grab sampling or periodic laboratory analysis cannot capture the dynamic changes that occur in CO₂ purity during normal operation. Variations in upstream capture performance, regeneration chemistry, or compression conditions can introduce spikes in impurities at any moment.

Continuous online monitoring allows operators to:

- Detect impurity excursions before corrosive species form

- Protect pipelines, compressors, and storage infrastructure

- Maintain compliance with purity specifications

- Track long-term performance for CCUS reporting and assurance

Real-time data is not optional for CO₂ transport — it is central to ensuring safe, reliable operation.

"Detecting trace impurities requires a measurement approach that works continuously in a high-CO₂ environment."

FTIR Spectroscopy: A Practical Method for Tracking Impurities.

Fourier Transform Infrared (FTIR) spectroscopy has become a preferred approach for CO₂ purity assurance because it can detect multiple contaminants simultaneously at extremely low levels. FTIR provides:

- ppb–ppm detection limits

- Accurate performance in high-CO₂ and high-CH₄ backgrounds

- Real-time, continuous measurement

- Excellent linearity across broad concentration ranges

This makes FTIR well-suited for operators who need certainty around water, NOₓ, SOₓ, H₂S, oxygen, and other reactive species.

How FTIR supports CO₂ purity monitoring

See how the MAX IR™ FTIR Analyzer enables continuous detection of trace impurities in high-CO₂ streams.

The Thermo Scientific™ MAX-Bev™ System: Designed for CO₂ Purity.

The MAX-Bev System is built specifically for unattended, long-term operation in demanding industrial environments. Key capabilities include:

- 24/7 operation with 99.7% uptime

- Factory calibration for life — no field calibration required

- Automated monthly validation with traceable QA records

- Multi-stream scalability (up to 10 sample streams)

- Full integration with DCS/SCADA/HMI systems

- Proven performance for low-level impurities in CO₂ and methane-rich streams

For operators responsible for CCUS pipelines, these features translate into confidence: the system is always measuring, always validating, and always ready to alert when impurity levels begin to rise.

Looking Ahead: Purity Monitoring as CCUS Infrastructure Expands.

As CO₂ transport networks grow — with longer pipelines, larger hubs, and more injection sites — purity monitoring will become foundational to safe, long-term operation. Corrosion events can compromise not only physical assets, but confidence in CCUS as a whole.

Technologies such as FTIR, when paired with automated validation and robust data integration, provide operators with the assurance needed to scale CCUS safely.

Conclusion.

CO₂ transport may appear straightforward, but its chemistry is not. Trace impurities can drive the formation of powerful acids that compromise pipelines and storage wells, even at concentrations previously considered acceptable.

Continuous, precise monitoring is the most effective defence. With FTIR technology and systems such as the Thermo Scientific™ MAX-Bev™, operators can detect impurities early, prevent corrosion, maintain compliance, and protect the infrastructure that CCUS depends on.

Be the first to read our articles

Written by Samuel Evans

Global MAX Business Development Leader at Thermo Fisher Scientific

Write to us at: info@novatech.ca