Written by J.C. Arènes – VP Sales & Service

November 5, 2025

Anyone who has spent time around an amine-based carbon capture unit knows that success rarely depends on one big piece of equipment. It is not just about the absorber tower or the regenerator; it is about what happens inside the liquid streams that connect them.

The solvent, typically an amine solution, does the real work. It absorbs CO₂ from the flue gas, carries it through the cycle, and releases it again during regeneration. When that solvent starts to degrade or when its chemistry drifts outside the optimal range, capture efficiency drops quickly and reliability follows.

In most systems, the rich solvent is the amine solution after it has absorbed CO₂ in the absorber, while the lean solvent is the regenerated, CO₂-stripped solution returning to the absorber. These two streams define the heart of the capture loop.

That is why understanding and monitoring solvent composition is not optional. The more precisely you can measure amine and CO₂ concentrations in the lean and rich streams, the better you can control the process, optimize energy use, and extend solvent life.

What you’ll learn:

- How solvent-side monitoring directly impacts capture efficiency and operating costs

- Why real-time liquid analysis provides an advantage over traditional lab testing

- The growing role of Raman and Near-Infrared spectroscopy in solvent analysis

- Which key parameters reveal solvent health and system performance

- How continuous monitoring supports environmental compliance and long-term stability

Why Solvent Monitoring Matters.

Every tonne of CO₂ captured depends on maintaining the right balance between the lean and rich solvent streams. By accurately measuring amine and CO₂ concentrations, operators can calculate CO₂ loading, the difference between what is absorbed in the absorber and what is released in the regenerator.

These values are more than numbers; they are the foundation of process efficiency. If the solvent is too weak, it will not absorb enough CO₂. If it is too strong or degraded, it will increase energy use in the regenerator, raise corrosion risk, and potentially elevate emissions. Over time, that means higher operating costs and lower capture performance.

Continuous monitoring helps detect these shifts early, turning solvent management into a proactive, data-driven part of operations rather than a guessing game between lab results.

From Lab to Line: The Shift to Real-Time Spectroscopy.

For years, solvent monitoring relied on collecting samples and sending them to the lab for titration or density testing. These methods can work but are slow and disconnected from what is happening in real time. They also pose safety concerns, since collecting samples in the field can expose personnel to high temperatures, corrosive amine vapours, or pressurized lines that require strict handling procedures and protective equipment.

Process conditions can change quickly, especially in large capture units. Inline spectroscopy, particularly Raman and Near-Infrared (NIR), has made a measurable difference.

Raman spectroscopy has proven especially effective for the simultaneous measurement of amine and CO₂ concentrations in both lean and rich streams. It provides real-time, non-destructive monitoring directly in the process line. There is no waiting for lab results or risk of sampling delays, only continuous and accurate data to fine-tune operation.

Optimize your capture loop.

See how the Thermo MarqMetrix All-In-One Raman Analyzer brings real-time insight to solvent monitoring.

The Benefits of Continuous Solvent Analysis.

Real-time solvent monitoring brings tangible gains in efficiency, reliability, and control. It allows operators to:

- Determine CO₂ loading and capture efficiency, setting the optimal recirculation rate in the absorber

- Track amine strength and detect degradation, keeping solvent quality in the ideal operating window

- Optimize process performance, minimizing steam consumption in the regenerator and reducing overall energy use

- Identify fouling or contamination early, before it affects throughput or uptime

Solvent-side analysis changes the operation from reactive to predictive. You are not just running the process; you are steering it.

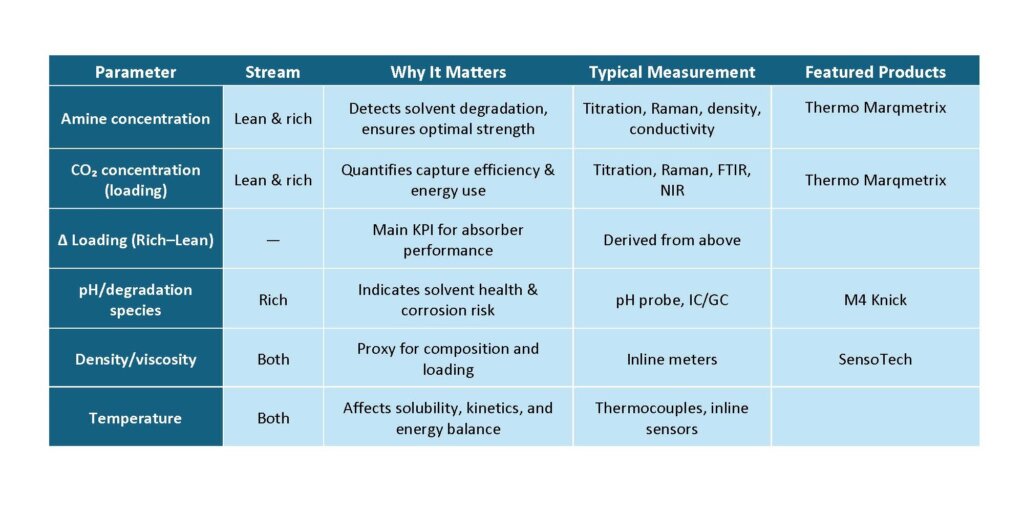

Key Parameters for System Performance.

Maintaining stable and efficient operation requires continuous tracking of a few essential parameters across the lean and rich amine streams.

Together, these parameters give a live picture of system health. With the right instruments in place, they feed directly into a control strategy that keeps the process running at peak performance while extending solvent life and reducing costs.

Keep your solvent steady, your data clear.

LiquiSonic uses ultrasonic insight for real-time control of amine concentration and CO₂ loading, keeping carbon capture performance on track.

A Foundation for Smarter Carbon Capture.

Optimizing a carbon capture process is not just about removing more CO₂. It is about doing it better. Gas-side verification is the other half of the measurement chain, and accurate CO₂ gas-stream monitoring helps confirm what enters and leaves the capture unit. Real-time solvent monitoring allows plants to balance absorber loading, regenerator energy, and environmental performance in one integrated view.

Technologies like Raman spectroscopy make that possible. By tracking solvent condition and CO₂ loading continuously, operators can sustain efficiency and compliance while extending solvent life and reducing OPEX.

Smarter carbon capture begins with better visibility, and that visibility starts in the liquid phase.

Be the first to read our articles

Written by Written by J.C. Arènes – VP Sales & Service

Write to J.C. at: Arenesjc@novatech.ca