Written by Jim Kapron – Technical Sales Representative

December 4th, 2025

Pulling CO₂ out of ambient air demands more than chemistry — it demands dependable data and tight process control.

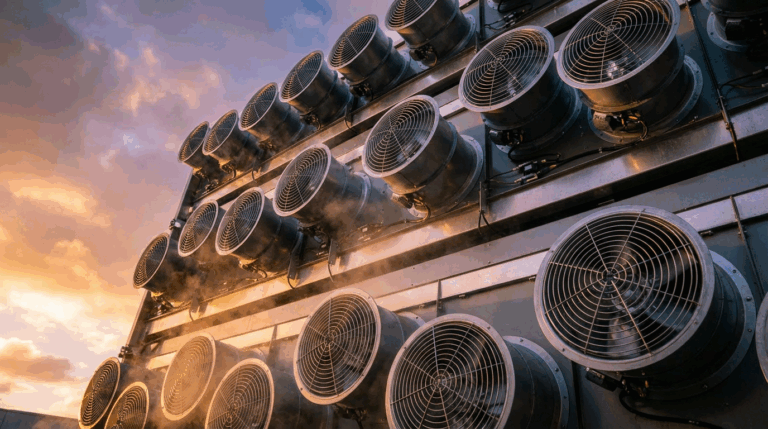

Direct Air Capture (DAC) has moved from concept to operating units, and the practical realities become clear as soon as you stand beside one. Ambient air contains only a few hundred parts per million of CO₂. Separating that small fraction from nitrogen, oxygen, and moisture requires tight control of sorbents, temperatures, and regeneration steps — and none of that control is possible without stable, representative measurements.

For process engineers, understanding how to monitor these parameters is essential for optimizing efficiency, ensuring safety, and meeting regulatory standards. This article explores the analytical technologies offered by Novatech Analytical that enable precise gas mixture measurement in DAC applications.

What you’ll learn in this article:

By the end of this piece, you’ll understand:

- Why low CO₂ levels in ambient air create demanding analytical requirements

- Which gas and liquid measurements support the full DAC cycle

- How TDL, NDIR, FTIR, Raman, and ultrasonic technologies complement one another

- Where measurement errors typically occur in DAC systems

- How instrumentation supports safer regeneration and better energy use

- Practical checks engineers can apply immediately in the field

The Challenge of of Measuring Gas Mixtures in DAC.

Ambient air contains approximately 400 ppm of CO₂—just 0.04% by volume—making its separation from nitrogen, oxygen, and water vapour a technical challenge. DAC systems typically employ either liquid sorbents (such as alkaline solutions or amines) or solid sorbents (such as zeolites or metal-organic frameworks) to capture CO₂.

During operation, engineers must monitor:

- CO₂ concentration before and after capture

- Residual oxygen and nitrogen levels to verify system integrity

- Moisture content to prevent sorbent degradation

- Trace gases that may affect sorbent performance or downstream compression

Accurate measurement of these components ensures optimal sorbent utilization, minimizes energy consumption during regeneration, and validates compliance with carbon reduction goals.

Key Measurement Technologies for DAC.

Novatech Analytical provides a suite of advanced instruments tailored for gas analysis in carbon capture environments.

- Tunable Diode Laser (TDL) Spectroscopy

Ideal for in-situ CO₂ monitoring in process streams. TDL analyzers offer high selectivity and fast response times, making them well-suited for real-time control loops.

- Non-Dispersive Infrared (NDIR) Analyzers

A proven technology for measuring CO₂, CO, and CH₄ concentrations. NDIR systems are robust and reliable for continuous monitoring in demanding environments.

- Fourier Transform Infrared (FTIR) Spectroscopy

Enables multi-component analysis — including CO₂, CO, H₂O, and trace hydrocarbons — in a single measurement cycle. FTIR is particularly valuable for complex gas mixtures encountered during sorbent regeneration.

- Raman Spectroscopy

The MarqMetrix™ All-In-One Process Raman Analyzer from Thermo Fisher provides real-time, in-line analysis of liquid sorbents and gas mixtures, ensuring concentration control and preventing chemical imbalances.

These technologies collectively address the diverse analytical needs of DAC systems, from ambient air intake to compressed CO₂ output.

Monitoring Liquid Sorbent Systems.

Liquid-based DAC systems rely on chemical absorption, often using strong bases or amines. Maintaining the correct concentration and purity of these solutions is critical for capture efficiency.

The LiquiSonic Concentration Analyzer uses ultrasonic velocity measurement to deliver precise, real-time data on sorbent concentration. This allows engineers to:

- Detect dilution or contamination early

- Optimize regeneration cycles

- Reduce chemical waste and operational costs

By integrating LiquiSonic with Raman spectroscopy, operators gain a more complete view of both physical and chemical properties of the sorbent solution.

Gas Analysis During Sorbent Regeneration.

Regeneration is energy-intensive and involves releasing concentrated CO₂ from the sorbent. Here, accurate gas composition measurement is vital for:

- Energy optimization: Monitoring CO₂ purity ensures efficient compression and storage

- System integrity: Detecting oxygen ingress warns of potential leaks within the system

- Process validation: Continuous emissions monitoring systems (CEMS) confirm adherence to environmental regulations

The T2500 CEMS Analyzer combines NDIR and electrochemical sensors to provide real-time data on CO₂, CO, SO₂, NOₓ, and CH₄. For portable applications, the GT6000 Mobilis FTIR Analyzer offers flexibility for sampling hot, wet, and corrosive streams.

Integration and Data Management.

Modern DAC facilities demand seamless integration of analytical instruments into distributed control systems (DCS). Novatech analyzers support:

- 4–20 mA and digital outputs for process control

- Bluetooth connectivity for remote configuration and data logging

- Cloud-based analytics for predictive maintenance and performance benchmarking

These capabilities allow engineers to make data-driven decisions that reduce downtime and improve overall system reliability.

Continue exploring the Carbon Capture in Focus series

Find all published articles in our Carbon Capture in Focus series, updated as new content is added.

Why Precision Matters.

In DAC operations, even minor deviations in gas composition can cascade into meaningful efficiency losses.

Examples include:

- Inaccurate CO₂ readings during regeneration that lead to over-compression and wasted energy

- Undetected moisture that degrades sorbents and increases replacement costs

Deploying advanced measurement solutions helps engineers achieve tighter control, lower operating costs, enhance compliance, and scale DAC technology more effectively.

Looking Ahead: The Role of Analytics in DAC Innovation.

As DAC moves from pilot projects to industrial-scale deployment, the demand for real-time, high-precision analytics will grow. Future developments such as AI-driven optimization and digital twins will rely heavily on accurate sensor data.

Novatech Analytical is positioned to support this evolution with technologies that measure reliably and help engineers run safer, more efficient carbon capture systems.

Conclusion.

Direct Air Capture is often described as a breakthrough technology, but in practice its success depends on something far more familiar to process engineers: stable, accurate measurement. When CO₂ sits at only a few hundred parts per million in ambient air, the entire operation hinges on how well each instrument tracks concentration, moisture, sorbent condition, and regeneration chemistry.

By applying proven analytical tools — TDL, NDIR, FTIR, Raman, ultrasonic concentration measurement, and integrated CEMS — engineers can operate DAC units with tighter control, lower energy intensity, and clearer awareness of system health. Reliable measurement is what turns DAC from an energy-heavy concept into a manageable, optimizable process.

The path forward for DAC will involve scale-up, digital integration, and more sophisticated control strategies, but the foundation remains the same: every efficient tonne of CO₂ captured begins with good data.

Be the first to read our articles

Written by Jim Kapron – Technical Sales Representative

Write to me at: kapronj@novatech.ca