Written by J.C. Arènes

VP Sales & Service

March 20, 2025

The Canadian Standards Association (CSA) plays a crucial role in defining the safety, performance, and installation standards for gas detection systems in Canada. Gas detectors are vital in industrial environments where hazardous gases pose risks to worker safety and operational integrity. Compliance with CSA standards ensures that gas detection equipment meets strict safety requirements, functions reliably, and adheres to national regulations.

CSA is also responsible for the Canadian Electrical Code (CEC), which establishes wiring and protection standards for all electrically powered equipment, including gas detectors. Understanding these standards is essential for engineers, service technicians, and safety professionals working in hazardous and non-hazardous environments.

What you’ll learn in this article:

By the end of this article, you will understand:

The role of CSA in establishing safety and installation standards for gas detection in Canada.

How CSA certification impacts the installation of gas detectors in hazardous and non-hazardous locations.

Why combustible gas detection requires additional CSA certification and how it affects compliance.

The importance of CSA compliance in ensuring workplace safety, regulatory approval, and system reliability.

Key Considerations for Gas Detector Installation.

Several factors determine their certification and compliance requirements when installing fixed gas detectors. These include:

- Is the detector being installed in a non-hazardous location?

- Is the detector being installed in a hazardous location?

- Will the detector be used to measure combustible gas concentrations?

Each of these scenarios requires adherence to specific CSA guidelines to ensure proper installation and safety compliance.

Non-Hazardous Locations.

Gas detectors installed in non-hazardous locations must meet CSA electrical approval requirements from an accredited certification agency if they operate at voltages above 30V. This ensures that the equipment has been tested for electrical safety and performance before being deployed.

However, if a device operates at 30V or lower, it is considered low-voltage equipment and does not require a formal certification mark. Even so, following CSA guidelines remains best practice to ensure safety and system reliability.

Hazardous Locations.

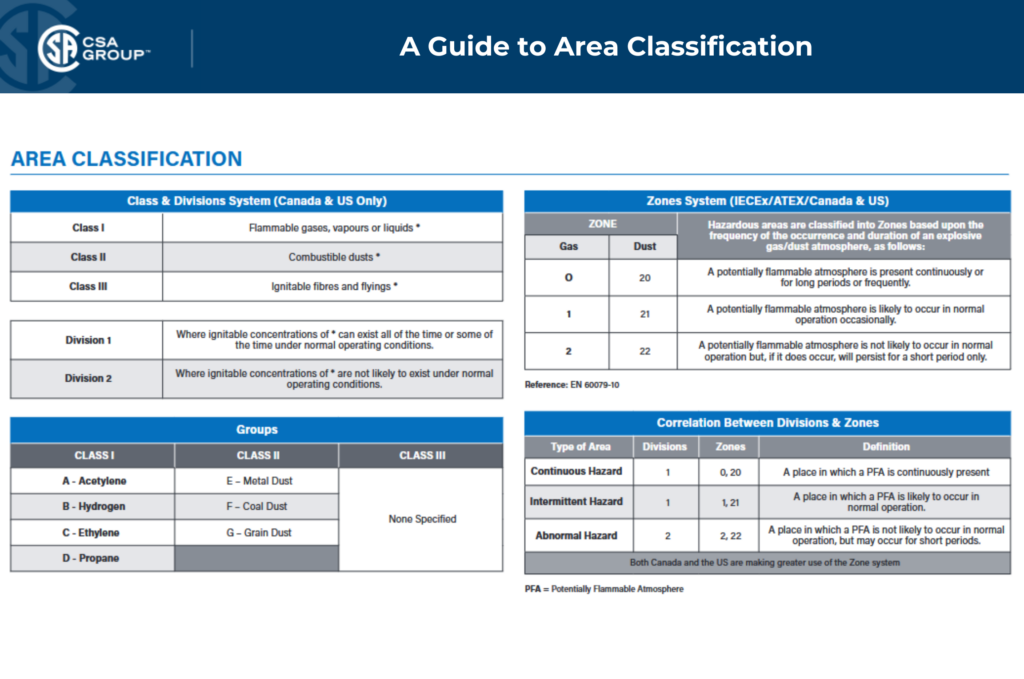

Gas detectors installed in hazardous locations—areas where flammable gases, vapours, or combustible dust may be present—must meet more stringent certification requirements. All equipment, regardless of voltage, must be certified for the specific hazard level of the installation site.

Certification requirements are based on hazard classifications:

- Zone 1 certification allows installation in both Zone 1 and Zone 2 environments.

- Zone 2 certification is limited to Zone 2 and cannot be installed in Zone 1 locations.

Gas detectors in hazardous locations must carry a certification mark with a small “C” (e.g., FMc, cTUV), indicating CSA compliance.

Combustible Gas Detection: Special Certification Requirements.

Additional certification is required under CSA Standard C22.2 No. 152-M1984 for gas detectors specifically designed to measure combustible gas concentrations.

This standard governs:

- Construction requirements – Ensuring detectors are built to withstand industrial conditions.

- Performance testing – Confirming accurate and reliable gas detection in hazardous environments.

- Sensitivity and response time – Ensuring early detection of flammable gas leaks.

Devices certified under CSA C22.2 No. 152-M1984 meet strict safety criteria for detecting combustible gases or vapours in industrial and commercial settings.

Why CSA Compliance Matters.

CSA certification is more than just a regulatory requirement—it ensures that gas detection systems are safe, reliable, and legally compliant. Following CSA standards provides several key benefits:

- Enhanced Workplace Safety – Properly certified gas detectors protect workers from hazardous gas exposure.

- Regulatory Approval – Compliance with CSA standards ensures legal operation under Canadian safety regulations.

- Reduced Risk of Installation Errors – Following CSA guidelines helps avoid costly mistakes and safety hazards.

- Long-Term Reliability – CSA-certified detectors are tested for durability and long-term performance.

For engineers, service technicians, and safety professionals, CSA compliance is essential to ensuring gas detection systems function effectively in hazardous and non-hazardous environments.

Need a CSA-compliant combustible gas detection that never requires calibration?

Discover the Power of the remarkable GD10P!

Conclusion.

Gas detection is critical for maintaining safe working conditions in industrial environments. Whether a gas detector is installed in a non-hazardous location or a hazardous Zone 1 or Zone 2 site, adherence to CSA standards is essential to ensure compliance, reliability, and worker safety.

Understanding CSA certification helps professionals make informed decisions about gas detector selection and installation. By following these standards, industries can minimize risks, improve operational safety, and maintain compliance with Canadian regulations—ensuring that the air we breathe remains safe for all.

Be the first to read our articles

Written by J.C. Arènes

VP Sales & Service

Write to me at: arenesjc@novatech.ca