Industrial environments are unpredictable, and some of the most dangerous threats are the ones we can’t see, smell, or hear. Hazardous gases present imminent and immediate risks—igniting in the air, causing toxic exposure, or displacing oxygen to lethal levels. Without reliable detection, these dangers remain invisible until it’s too late.

Gas and flame detection systems serve one purpose: to provide the earliest possible warning of a hazard. While flame detectors identify the presence of fire, gas detectors focus on monitoring hazardous gases that could lead to explosions, poisoning, or oxygen depletion.

Gas hazards generally fall into three categories:

Combustible (or explosive) gases

Toxic and/or corrosive gases

Oxygen-related hazards

Understanding these risks—and how to detect them before they escalate—is key to ensuring workplace safety.

What you’ll learn:

How combustible gases lead to fires and explosions, and why LEL monitoring is critical.

The risks associated with toxic gases and why exposure limits must be strictly controlled.

How oxygen depletion and enrichment create life-threatening conditions.

How different gas detection technologies work, and how to select the right system.

Best practices for implementing an effective gas detection strategy.

Combustible Gases: The Silent Firestarter.

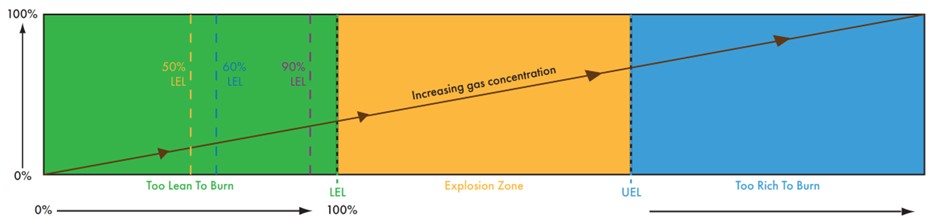

Combustible gases pose a significant threat in industrial environments, as they can ignite and cause explosions when mixed with air at the right concentrations. The key measurement in detecting these gases is the Lower Explosive Limit (LEL)—the minimum concentration at which a gas can ignite in the presence of an ignition source.

As an example, the LEL of methane (CH₄) in air is 5.0%. In other words, concentrations of methane below 5.0% are not flammable (there is insufficient fuel). Similarly, at very high concentrations, the gas can exceed the Upper Explosive Limit (UEL) where there is insufficient oxygen to support combustion.

The LEL concentration is unique to a given combustible gas. For example, the LEL of hydrogen (H₂) is 4.0%.

One never wants to reach the LEL of a gas, and thus combustible gas detectors are designed to operate in the safe zone—below 100% of the LEL. Alarms are set to trigger warnings and corrective actions at values defined as percent LEL, ensuring early intervention.

Various technologies exist to detect combustible gases, but care must be taken to ensure that the gas most likely to be present is detectable. In environments where multiple gases may coexist, detection strategies must account for potential cross-sensitivities. A trusted gas detection expert is critical in these circumstances.

Toxic and Corrosive Gases: Invisible Killers.

Some gases don’t explode—but that doesn’t make them any less deadly. Toxic gases cause harm through direct exposure, inhalation, and long-term absorption, often without any warning signs.

Industrial operations regularly involve toxic or corrosive gases that can be harmful even at very low concentrations. Some of the most common include:

- Carbon monoxide (CO)

- Hydrogen sulfide (H₂S)

- Ammonia (NH₃)

- Chlorine (Cl₂)

- Nitrogen dioxide (NO₂)

- Phosgene (COCl₂)

- Hydrofluorocarbons (HFCs)

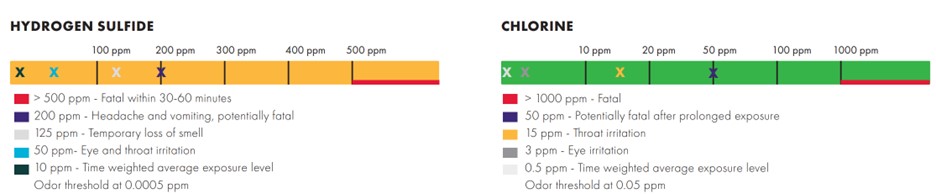

Organizations such as The Occupational Safety and Health Administration (OSHA) detail exposure limits for these hazardous gases. In some cases, such as hydrogen sulfide (H2S) and chlorine (Cl2) shown below, concentrations in the low parts per million (ppm) are considered harmful. Even concentrations below 1000ppm can prove fatal.

Gas detectors for these types of hazards are typically designed to detect a single gas, or gas family. The detection ranges must ensure adequate warning at concentrations below harmful levels. In some applications, processes may contain fluids which are both combustible and toxic.

Ensure workplace safety with expert guidance!

Oxygen Hazards: Too Much or Too Little?

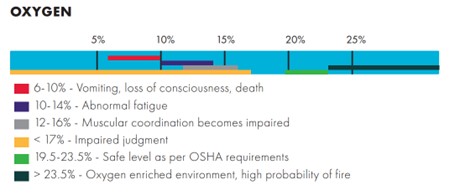

Oxygen is essential for life, and under normal conditions, presents no threat to personnel. There are conditions, however, that may arise in certain industries where oxygen levels are outside of the safe zone. As illustrated below.

Oxygen Deficiency (Asphyxiation Risk).

Low oxygen levels can occur in confined spaces where another gas—potentially one that is not harmful on its own—displaces oxygen to dangerous levels. Nitrogen (N₂) is often used in industrial processes. A leaking nitrogen tank or pipeline in an enclosed space can create a hazardous atmosphere.

Since nitrogen is inert and difficult to measure directly, the recommended approach is to monitor oxygen levels instead. This ensures a safe breathing environment for personnel while also serving as an indicator of another gas leak if oxygen levels begin to drop unexpectedly.

Oxygen Enrichment (Fire and Explosion Risk).

Conversely, there are industrial processes that require pure oxygen, creating a heightened risk of combustion. A leaking oxygen line significantly increases fire hazards, even at lower concentrations of combustible gases.

As discussed in the combustible gas section, fire requires three elements—fuel, oxygen, and heat. When excess oxygen is present, materials that would typically require high ignition temperatures can ignite much more easily, leading to a greater risk of fire or explosion.

Oxygen Detection Strategies.

Oxygen gas detectors are commonly designed to measure both depletion and enrichment. Since oxygen hazards can fluctuate in both directions, proper monitoring ensures that levels remain within a safe range at all times.

Mitigating Risks Through Reliable Gas Detection.

Industrial gas hazards—whether combustible, toxic, or oxygen-related—require a proactive approach to detection. The right gas detection technology, combined with proper training and response protocols, ensures workplace safety and regulatory compliance.

Key Takeaways:

✔ Combustible gases require LEL monitoring to prevent fires and explosions.

✔ Toxic gases can be deadly at low concentrations—real-time detection is critical.

✔ Oxygen levels must remain stable to prevent asphyxiation and combustion risks.

✔ Gas detection is not a one-size-fits-all solution—systems must be customized for each environment.

Are You Confident in Your Gas Detection System?

Safety depends on early detection and fast action. If your gas detection strategy isn’t comprehensive, up-to-date, or tailored to your environment, now is the time to reassess. The risks may be invisible—but with the right detection systems in place, they don’t have to be unpredictable.

Be the first to read our articles